Darlow Rosettes Environmental Planning 2024

- Who we are and our values

- On Site

- Product

- Packaging

- Supply

- Customer

Who we are and what we stand for

- Our values

Onsite

- Carbon footprint of workforce

- Carbon footprint of building

- How to reduce energy consumption

- How to improve efficiency.

Product

- Dissect product into components.

- Investigate constituent parts.

- Compare alternatives.

- Look at future products and innovations.

Packaging

- List all packaging materials.

- How we have improved

- Future plans

Supply Chain

- Understand our suppliers.

- Review supply products.

- Look at alternatives.

- Look at values.

Customer Choice

- Educate customer on how we work.

- Signpost products so customers can make informed decisions.

- Be honest and open with what we do and what we can’t do.

- Welcome feedback.

- Engage with customers and wider audience in a positive and polite manor.

1) Who we are and our values

We have been making rosettes for nearly 35 years, and our values have remained unchanged during this time. Our goal has always been to create and sustain a profitable business by offering products that customers want to buy and most importantly, buy again. When they do, it means we’re doing things right! Our long-standing customers, some of whom have been with us for decades, are a testament to the quality of our products and our commitment to service. Each rosette bearing our name symbolises our pride and dedication to our core values.

We are fortunate to have a hardworking and loyal workforce, essential to our business’ success. This loyalty reflects how we treat our employees, fostering a dedicated team. Alongside this, we not only have a loyal customer base but also a loyal supply chain with partners we’ve collaborated with for many years.

Change is inevitable, and we continuously seek ways to improve. Our pioneering use of digital hot foil print technology has revolutionised our business, opening up new opportunities for success and Darlow Rosettes leads the market in this regard. We are also conscious of the growing importance of environmental sustainability and like many others, we aim to contribute to a sustainable future. We are critically evaluating our operations to enhance our sustainability practices, making it a core aspect of our business ethos.

The UK contributes 1% to the world’s carbon emissions, but that doesn’t mean we cannot improve. As a small business, our carbon output is incredibly small. Simply getting our staff to work has a much higher impact than our onsite activities. Fortunately, all our staff live within 10 miles of our site, so their commutes are short. As a manufacturing business, there is less scope for working from home, but we do so whenever practical.

We are conducting an energy review of our building to identify ways to reduce our energy use and maximise efficiency. We have already replaced all lights with highly efficient LED bulbs and ensure that lights and plugs are only on when necessary. Our electricity is 100% renewable.

We recycle as much as possible for reuse in our packaging and increasingly select sustainable office products. We are also researching credible, UK-based carbon-neutral schemes with a long-term goal to go even further. Looking at Scope 1-2 and 3 to see how we can get to Net Zero, will also play an important part of our future planning

What is your rosette made from?

| Component | Material | Recycled / recyclable | Notes |

| Ribbon | UK made | 100% Recycled | Not currently |

| Card centre | FSC UK card | recyclable | |

| paper sewing guide | Paper | Recyclable | |

| Paper back | Paper | Recyclable | |

| Bridle clip / pin | Metal | Metal – recyclable | |

| Staple | Metal | Metal – recyclable | |

| Pleating thread | Cotton | Cotton – recyclable | |

| Sewing thread | Cotton | Cotton – recyclable | |

| Centre foil | Resin foil | recyclable | |

| Tail foil | Thermal foil | unclear | |

| Glue | No | Options available | |

| Centre ink | UK made | Natural inks – recyclable |

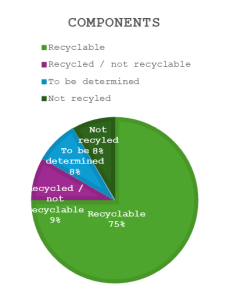

A BD rosette consists of

- 12 individual components.

- 9 items are 100% recyclable.

- 1 item 100% recycled.

- 1 item to be determined.

- 1 item not recycled/recyclable.

75% of components recyclable

Is a rosette a single use plastic item?

- Not as defined by EU and UK

What is a Rosette?

In the modern context, a rosette is an achievement based award. It is woven into the fabric of competition and is deeply valued by competitors at every level.

A rosette holds great value and reminds us why we strive. Everyone remembers their first rosette, it marks a moment in time with lifelong memories and we believe that a well-made rosette deserves appreciation as the lasting keepsake that it is, often cherished by recipients for years to come.

Multi-medalled Paralympian Sir Lee Pearson told ‘Country Life’ in an interview that he keeps all his championship rosettes in a ‘3ft by 2ft, gold-edged frame’. However, one that means almost as much is a far less flamboyant frilly, collected when he was just 15 years old with a mare called ‘Tacky’. “I’d lost my confidence, then Tacky came along and, together in a local able-bodied dressage class, we finished in the frame. That rosette literally changed my life.”

A rosette is not a throw away item, never has been and never will be. We will continue making rosettes as long as there are customers to serve.

Environmental Impact Concerns

Rosettes have been described as a “single-use plastic,” which has raised concerns about their environmental impact. We believe that this label is clearly incorrect in this context.

We recognise that the ribbons used by most rosette companies have an impact as they are made from plastic. However, our ribbon supplier now uses recycled plastic, significantly improving the sustainability of our rosettes.

Alternative Products to Rosettes

An alternative to rosettes would need to feature the same text and sponsor details, offer multiple colour options, and fit within the same budget. We have seen many suggestions, but none seem to be credible alternatives. Alternatives such as:

Chocolate

- Issues with heat and melting—solution requires refrigeration, which uses more energy

- Ethical concerns about cocoa bean sourcing and air miles

- Difficult to brand effectively

- Likely more expensive than a rosette

- Not a credible alternative and could harm the issuing body

Prize Money/Free Entry

- Given the average cost of a rosette, £1.60 is not much of an incentive

Tote Bags

- Could be branded, but lacking the correct details and colours

- Limited demand for multiple tote bags

- Possibly more expensive than a rosette of the same specification

- Environmental concerns regarding materials used

Free Tea/Coffee

- A nice gesture, but not memorable

- Significant environmental impact

- Difficult for sponsors to gain value

Prize Cards/Certificates

- Commercial printers are not interested in low volumes needed for individuality of designs

- Potentially more expensive

- Significant environmental footprint of paper

- Less robust than a rosette, with issues related to weather, storage, and handling

- Not as special as a rosette

Alternatives to Satin Ribbon

The main alternative ribbon is acetate, made from wood pulp. However, acetate ribbons do not have the visual impact demanded by the market. The open weave of acetate ribbons poses challenges for thermal printers, the industry standard for printing on rosette tails. Thermal printers cannot achieve acceptable print quality on acetate ribbons compared to satin. Acetate ribbon is also less crease-resistant than satin, which can be problematic for storing rosettes before awarding. Creased ribbons do not present well and can negatively affect the sponsor’s brand and the organisation.

Acetate is marketed by some rosette companies as eco-friendly and compostable. We approached our ribbon manufacturer to explore acetate more closely. Cole Fabrics provided us with a detailed analysis comparing various ribbons’ eco credentials, for which we are very grateful. See below.

Other materials like paper, Tencel, and cotton are not suitable for rosette making in their current form. There are many issues with production and colour consistency, making these materials unviable.

Increasingly, we will also consider our suppliers’ sustainability plans to ensure alignment with our values and those of our customers.

- Yarn is produced by American company Eastman, under the brand name Naia™

- The yarn is made from Pine and Eucalyptus trees that are FSC and/or PEFC certified.

- BUT the trees are harvested and cut down before maturity meaning they offer little to no carbon dioxide removal from the atmosphere.

- The trees are debarked and converted into wood chips. The chips enter a digester that contains acetic acid (the main constituent of vinegar). This solution turns the wood chips into a pulp and aids the release of cellulose, the main compound found in plant cell walls.

- The cellulose is dissolved in acetone, which is the chemical is commonly found in nail varnish remover and this reaction causes the cellulose to become a thick liquid. The acetone used is recycled back into the system for reuse, creating a closed loop step.

- This thick liquid is passed through a filtration system to remove any impurities before being extruded to make filament, which in turn makes the yarn.

- The yarn is then woven, dyed and prepared for shipping.

- Acetate 750YY base yarn is certified to biodegrade by the manufacturer Naia™Finished dyed ribbons have not been tested as compostable or biodegradable

It costs £13,136 per colour to certificate which is not economically viableTherefore, it should not really be described as biodegradable

608 Mechanically Recycled Polyester (rPET)

- Clean water in Asian countries such as China, The Philippines, Thailand, India and Vietnam is only accessible through bottled water. Aging pipelines and contamination make tap water unsafe in these regions.

- This results in millions of plastic bottles ending up as waste on the land and in the sea. We utilise this abundance of waste to create our recycled polyester, as the raw material incurs no production cost.

- We have been manufacturing this product using post-consumer water bottles for over 15 years.

- The PET water bottles are collected from the greater Shanghai area, before being washed, crushed and shredded to form flakes.

- The flakes are washed to remove any contaminants and impurities before being melted and extruded to make filament, which in turn makes a yarn.

- The yarn is then woven, dyed and prepared for shipping.

End of Life

In theory, recycled polyester 608 ribbon can be chemically recycled. However, the global waste infrastructure for this is not yet in operation. There are companies doing research on this, such as Worn Again ( https://wornagain.co.uk/).

.

We advise and promote the re-use of our products to help reduce the environmental impact we all have on the planet.

Comparing Ribbons

Coles use The Higg Index Material Sustainability Index (MSI). This tool facilitates an evaluation of the environmental ramifications associated with the various stages to create a fabric. Employing a cradle-to-gate (raw material to factory gate) approach, the MSI relies on life cycle impact assessment (LCIA) data and methodologies to quantify fabric-related impacts. The MSI database is commonly used for fabrics found within apparel, footwear, and home textiles.

The data is collected from the following sources.

- Generic averages, e.g. data sourced from locations with the highest material specific production to assess each environmental impact per stage.

- Peer reviewed journals

- Contributions by brands

| 1 Kg Raw material to Yarn | Global Warming Potential Kg CO2e |

| Acetate 750YY – Tree to Yarn | 4.18 |

| 608 – Oil to Yarn | 3.98 |

| rPET 608 – Bottle to Yarn | 1.29 |

Conclusion

- Acetate is far more harmful to produce than rPET 608

- rPET 608 is classified as a UK made product

Global Warming Potential Cradle to Gate (Nottingham, UK)

This is the total impact from raw material to finished item at the factory.

| Kg CO2e | |||

| Per 1Kg | Acetate 750 YY | 608 | rPET 608 |

| Raw Material Source | 3.06 | 2.74 | 0.05 |

| Yarn Formation Method | 1.12 | 1.24 | 1.24 |

| Weaving | 13.68 | 1.40 | 1.40 |

| Dyeing | 6.87 | ||

| Transport | 0.52 | 0.2 | 0.2 |

| Total | 25.25 | 5.58 | 2.89 |

| Kg CO2e | |||

| Acetate 750YY | 608 | rPET 608 | |

| 1 Metre of 25mm ribbon | 0.063 | 0.027 | 0.014 |

| Difference between materials | Reduction in Kg CO2e |

| Acetate 750YY and 608 | 58 % |

| 608 and rPET 608 | 48 % |

| Acetate and rPET 608 | 78 % |

rPET has a 78% reduction in Kg CO2e over Acetate

Disclaimer: These results have been calculated using primary data and the Higg MSI 3.7. They have been calculated by Cole Fabrics and are not third party verified.

The Future

With rPET 608 coming on stream for 2024 the environmental impact of this ribbon over virgin 608 is huge. It’s an almost 50% reduction in Kg CO2e so halving our carbon output for this product.

Whilst rPET is recyclable, this isn’t currently achievable due to the manufacturer dyeing process. But there is significant interest in this from fashion and clothing brands who want to be more focused on sustainability. A lot of investment is going into the science behind this, especially in the USA with the hope of bringing large scale recycling to fruition.

Bio Polyester

Cole Fabrics are also constantly striving to reduce carbon emissions and one of the ways they’re doing that is with the development of an exciting new ribbon product called bio polyester. This innovative material includes additives that create nutrient pathways for micro-organisms, making it biodegradable.

The aim is to integrate this into our rPET products for a sustainable end-of-life solution.

We aim for 100% recyclable packaging, utilising cardboard, LDPE 4 rosette bags, and paper-based materials.

| Item | Material | Recyclable |

| Box | Carboard | Yes |

| Rosette bags | LDPE 4 | Yes |

| Parcel tape | Paper | Yes |

| Address label | Paper | Yes |

| Address label pouch | Paper | Yes |

| Internal packaging | Reuse items | Yes* |

Our future plans

- Source plastic-free bags that meet our operational needs and customer requirements. This process is on-going.

- Monitor our packaging to make sure we maximise the amount of product that goes into each box.

- Minimise boxes used for multiple deliveries and follow on orders.

Eliminate any of our internal reuse packaging items that cannot be recycled, even if we have reused them.

We recognise that our supply chain has an impact on our carbon footprint. We have identified all our suppliers and have broken this down into product supplier and service supplier.

Product suppliers

This is a niche marketplace with very limited choice for some items, but all our suppliers are UK based. We prioritise UK-made products to support local businesses as much as possible. Our main products are either paper or ribbon which come with verifiable environmental credentials.

Service suppliers

We have identified the following sectors that provide service to our company:

- Energy

- Transport

- Financial

- Service

We will review all our partner companies using their sustainability credentials as a core metric for our continued business. This review will typically be conducted annually, depending on the services provided.

We believe that a rosette is something to treasure, not something easily cast aside. It should be well-made and last for decades. Our goal is to inform and educate our customers, so they value what they buy and understand that buying efficiently is not only cheaper for them but also better for the environment.

We are committed to making all claims with honesty and integrity, as trust in our brand is critical to our future success. Here’s how we plan to achieve this:

- Educate customers on how we work

- Signpost products so customers can make informed decisions

- Be honest and transparent about what we do and what we can’t do

- Welcome feedback

- Engage with customers and the wider audience in a positive and polite manner

Best Practice

We want customers to understand the benefits of our quantity price discounts. For example, buying 300 rosettes once a year instead of 150 twice a year can save a lot of money. This approach also reduces our carbon footprint due to more efficient production, less packaging, and fewer transport needs. It helps us plan production, staffing, and material purchases more effectively, and it makes our supply chain more efficient, contributing to further carbon reduction.

We encourage event centres and organisations to properly manage their existing rosette stocks and plan their orders in advance. This way, they avoid over-ordering and having unused rosettes, or under-ordering and needing to place follow-up orders, which results in more deliveries.

Our commitments include:

- Signposting eco-friendly alternatives on our website

- Developing a best practice guide for efficient ordering

- Surveying our customers on relevant topics to understand their needs and using the results to improve our products and services

- Creating a social media strategy to educate and influence a wider customer base about our products and sustainability strategies

The future offers significant opportunities for reductions through recycling and new biomaterials. Although we may not have all the answers today, it is crucial to allow the industry time to develop sustainable solutions. To achieve this, the industry needs confidence that products like rosettes have a future. It is vital for organisations to support us so we can all meet our climate goals.

Our aim is to be the most influential advocate and voice for rosettes within the industry.